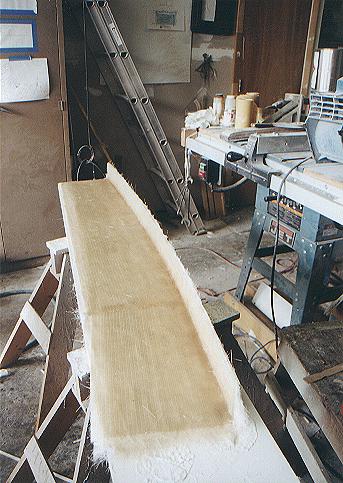

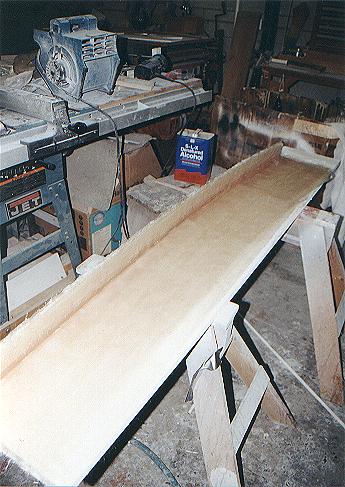

This project outlines a repair on a damaged swim platform. Several of the techniques used will also apply to other repairs involving fiberglass skin removal and replacement.  In this case the boat was improperly tied and allowed to butt into a concrete sea wall for several days before the owner discovered the mistake.  Using a standard Melamine shelf from a home improvement center and a strip of PVC Foam Board, a simple mold was prepared. The curve was traced from the swim platform using an 1/8' thick batten and the PVC strip was then hot glued into place. PVA release film was applied with a spray gun at 90 psi and allowed to cure for 2 hours in the sun.  Layup was done with 1/16" of white polyester gelcoat, 2 courses of 3/4 oz. mat followed with 2 courses of 8 oz. fabric, and finished with 2 more courses of 3/4 oz. mat. The polyester resin was catalyzed for a medium to slow kick.  The mold and layup was then vacuum bagged at 20" hg for the entirety of the initial cure. (About 2 1/2 hours) Both PeelPly and breather cloth were used  The part is now ready for removal from the mold.  After marking the outline of the part on the swim platform, the damaged and delaminated section of the skin was removed from the swim platform. Notice that the original skin, laminated to ply wood and Baltek, readily pealed away without even pulling any wood fiber in most areas. A case in point that polyester resin is a poor choice for composite cores over wood.  After allowing the wood to dry thoroughly, it is primed with straight epoxy, allowed to tack up, and then heavily buttered with epoxy thickened with cabosil and milled fiberglass.  Likewise, the repair part is primed and buttered. Between the two mating surfaces there is an excess of epoxy so that a void free bonding will take place.  The excess epoxy is squeezed out by using a roller and then clamping pressure. A 2x4 is used to spread the pressure across the center and near the edge. Shims were used to equalize and level the joining edges.

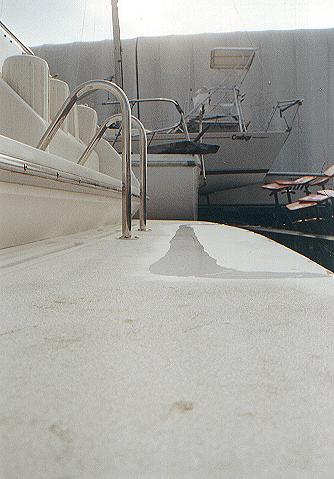

After the epoxy cured over night, the joint seam was under cut by about 1/8" and feathered back on either side by an inch. Using polyester gelcoat, the joint is floated out and sanded fair after the cure.  Next, two coats of matching polyester gelcoat were applied to the clean and sanded swim platform. The edges were sanded through 600 grit wet paper and buffed. A border was then taped out and a coat of gelcoat with non-skid was rolled on. The tape was pulled almost immediately so that the raised edge of the non-skid would be allowed to soften into the border. If you are painting rather than gelcoating, here's an alternative to adding the non-skid directly to the paint : Lay down a very wet coat of paint, immediately sift on a layer of non-skid, completely covering the paint. After the paint has cured, sweep away the loose excess non-skid and apply a thin second coat of paint This will seal the non-skid in and yield a uniform surface that is not so abrasive and will be easier to clean.  Some minor damage at the point of attachment was remedied by grinding down a bit and building a layer of reinforced epoxy over the area. Since polyester gelcoat will not bond to the epoxy, a bonding layer of Duratec Surfacing Primer was applied prior to the gelcoat.  The area of damage below and any remaining voids were filled in with reinforced epoxy, faired, coated with Duretec, and gelcoated to match. In all the repair took a little over 17 hours labor time and was completed within three working days. Have fun! Feel free to download and print this drawing, but please don't use it on a website without linking it to USAMARINE. It's part of our upcoming revisions and is sort of a preview, (for the gang here at the boatbuilding bulletin board), of some tips and techniques that I'm assembling for use in the Captains' Corner Projects area. Capt Patrick McCrary USAMARINE Web Group P.O. Box 30933 Palm Beach Gardens, FL. 33420 Telephone/Fax (561) 848-3366 Web site questions or comments to: webmaster@usamarine.net |