Page 1 of 4

spenting the next 3 months reinventing the wheel

Posted: Aug 24th, '09, 18:42

by bob lico

first indications are that wheel is not even round!!!! seriously rode a 65' paul mann and took a real good look at steering pod. for all of you with single lever controls from that guy in washington state that never returns a call i will have a solution very soon. using potentiometers and servos to control thottle and gears (fly by wire) for brother jk and myself. the 31 with capt patrick rudders will out turn out manever a 25' bertram ---------i garrantee it . are you listening bob h!!!!

Posted: Aug 24th, '09, 19:08

by randall

yeah...but my 25 with its itty bitty rudders still steers well on one engine. i wish i wasnt getting so much practice.

Posted: Aug 24th, '09, 19:27

by JP Dalik

And Kobelt already makes a set of single levers that work just fine. Why go electric when you can use Morse 44's

Posted: Aug 24th, '09, 19:39

by bob lico

jp- because it has a duel output that will be couple to a trolling valves

Posted: Aug 24th, '09, 20:02

by bob lico

jp another comparason is a present day mercedes/bmw that has one lever on the transmission. to the right and you shift as a stick ,to the left it shiefs auto. the single levers on the pod have 3 detents. first is foward, second is neutral , next engages trolling valve (cannot leave accidently in trolling position--impossible) ,as soon as you want to speed up like changing areas jusy push foward disengaging trolling and into regular mode.with the rolins single lever that some of us have now there is a 21/2" throw on the levers and 3" travel on the cummins engine so something has to give like 12 knots idle and 36knot cruise or 29 cruise and 5.8 kt idle speed.i will make this system work and then post the results for all of us.

Posted: Aug 24th, '09, 22:15

by Harry Woods

Bob,

Was that the dark blue or black hull Paul Mann hailing Palm Beach that has been docked in Hampton Bays for the past few weeks? Just an incredible vessel. You would need roller skates to tend the lines in that cockpit.

Harry

Posted: Aug 25th, '09, 06:51

by bob lico

harry just a perfect beautiful boat what can i say.

Posted: Aug 25th, '09, 08:48

by CMP

If anyone needs the Kobelt mechanical single lever controls, I have a set as well as a set of the Release handles. Unfortunately for me, I didn't buy them before I made the pod so they didn't fit...

CMP

Posted: Aug 25th, '09, 21:06

by bob lico

cmp i am not familar with this product why doesn`t fit the pod ? do you mean the physical size of the pod or what??

Posted: Aug 26th, '09, 05:10

by ianupton

Mark,

Can you send me a picture of what you have?

I was looking into this for my B25.

I'm going single so I want single lever, dual control and have a port side helm in my sport convertible.

Thanks!

Ian.

ian.upton at gm.com

Posted: Aug 26th, '09, 09:41

by JP Dalik

Bob,

The Kobelt controls are made to mount very similar to a standard Morse control. So in order to put them in a pod you have to build a bracket. Thst is what Jersey Cape did and then just used a Release or Scoponich handle. Its a nice simple control that allows plenty of throw for the Cummins application. We got ours from a Jersey Cape when the owner switched to electronic engines and controls.

The pod installation gets very wide when you have to install 2. We did our install prior to the pod being glassed to the boat. Still can get to the adjustments just was allot easier than working upside down.

Mark you wouldn't be able to tell me where to get a set of electric aeleron controls for the trolling valves would you?

Posted: Aug 26th, '09, 20:01

by Bob H.

Bob Lico, Im still listening...I have moved my exhaust to the outboard stringer...centubular muffs like JPs...bronze 6" through hullls like on the phoenix...filled holes and ready to install...I was wondering how to throw those trolling valves..need to fab a custom arm, it seems like the angle is not even close to pulling in a direction I need. Keep it simple....remeber I m gonna take a pinch of phoenix, a dash of chimera, a smidge of denada, a big plateful of comorant princess....keep me posted.

Posted: Aug 26th, '09, 20:21

by JK

Bob,

Is this fix to the Solo II's easy and relatively inexpensive?

--JK

Posted: Aug 26th, '09, 22:16

by bob lico

bob h be aware you put BOTH gear cables down starboard pillar along with starboard thottle. the port pillar gets only port thottle cable. this avoids the 180degree bent of the cables on the zf irm gears.nice straight cable with large radius in ceiling of cabin.the troll valves will be actuated electrically like ioo percent of the big boys. incidently all cabo`s have trolling valves so if you can go below on a 45' cabo you can clearly see how it is done.

jk i am just putting this together using twin disc potentiometers however in your case (selling the boat) why don`t you investigate jp`s idea with kobelt single lever. my case might become costly but the benifit of electric trolling valve is a incentive.i don`t know any thing about the kobelt single lever control or the bracket that has to be made to utilize it.

Posted: Aug 26th, '09, 22:41

by bob lico

bob h i just realize you have a bahia mar so cables in pillars do not apply but routing still does 3 on starboard and one on port.

Posted: Aug 27th, '09, 14:09

by JK

Bob,

When I first brought the boat out of the shed after the redo we had the throttles dialed in. I need to spend sometime and tinker with the linkage to get more RPM's out it....if I want to. 2600RPM and 26.5knts is plenty fast 99.9% of the time, especially when I know the engines are propped correctly, etc.

--JK

Posted: Aug 28th, '09, 00:49

by Raybo Marine NY

now im curious- what happens after the 3 months is up?

Posted: Aug 28th, '09, 09:00

by bob lico

robbie ----------you throw in the towel!!!!

Posted: Aug 28th, '09, 11:01

by Raybo Marine NY

no way man, you will be in too deep, it will be a quest and a obsession that is sure to end in casualties

Posted: Jan 23rd, '10, 11:35

by Raybo Marine NY

I cant remember what I had for lunch yesterday but for some reason this came to mind this morning-

How did you make out?!

Posted: Jan 23rd, '10, 12:00

by Carl

If you just need more throw wouldn't it make sence to just change linkage attachment points.

OR

Make up an adjustable linkage assemble. This could be as simple as a Hinged Rod where the two cable get mounted. The lower cables throw would be increased the higher you place the second cable along that rod. When you find that perfect spot, lock it up. Scared of it loosening up, screw or wire it in place....or give a nice tack weld.

I know it's been done...but Fly by Wire in a saltwater environment really scares me.

My .02

Carl

Posted: Jan 23rd, '10, 15:29

by Mikey

I ripped out those cheesy pot-metal Morse controls and replaced with Kobelt. All S/S and internal brass, easily adjusted, smooth as silk and they look great!

Posted: Jan 23rd, '10, 16:22

by Charlie J

very nice mikey, and neat and clean

Posted: Jan 23rd, '10, 18:40

by bob lico

well robbie it like this the doctors all concur they cannot put me back together again.the end of the femor bone forms the sockett for the knee mine has multible fractures and knee replacement does not replace femor bone! that slow me down a bit so i am taking one step at a time (no pun intended) .went all out on the interior cabinetry and that is coming along real nice trying to take my mine off repairing gouges in hull side from flygaff. irmon and me don`t get along together and i fear another fiasco .i will concentrate on controls and putting dual c-120 raymarine in dash board after attemping paint job.

Posted: Jan 24th, '10, 00:46

by coolair

screw the controls I want to see the dual c120s

Posted: Jan 24th, '10, 05:54

by bob lico

coolair i upgraded the c-80 unit on the left to a 120 last year.they talk to each other by sea talk but i usually leave the entire screen on the left dedicated to digital sonar thru raymarine dsm. (digital sonar modular).the unit on right is full screen gps (navionics gold) with raymarine digital radar overlay thru smart heading sensor.

Posted: Jan 25th, '10, 09:51

by Rawleigh

I think Robbie is onto the solution for you guys. A simple bell crank arrangement in the overhead would allow you the ability to get an infinite and incremental increase in throw without having to get the adjustment out of the controls. You could actually do it on a single arm type bellcrank. The bad news is you would need new two new shorter cables for each function. Put the cable from the control inboard on the arm and the cable to the engine outboard so that it gets greater throw. You may need to use a little more effort at the lever, as you will loose a little mechanical advantage, but it would work! A simple piece of strap aluminum with a bolt through a bronze bushing at the fixed end would work. Drill a series of holes further out the strap to allow gross adjustment of the cables.

Posted: Jan 25th, '10, 12:54

by bob lico

Rawleigh in light of the fact the 3" arms on a typical gear/thottle arragement compare to the 8" arms of the solo single lever controls ,the mechanical advantage is not a factor in fact i wish there was a little more drag. robbie has a good idea there and i would like to calculate some kind of ratio you would derive from differant lenths of the bellcrank .most likely mount on cummins engine by making a bracket and then a theaded ss rod to the fuel pump linkage. i guess i really did not explain the problem and that is why sim is indicating adding to cable lenth. the throw of the lever on the solo control is 13/8" forward and 13/8" reverse . adjusting the cable lenth on changes you position on the thottle lever but throw never changes so you could idle at 900rpm and attain 2700rpm or idle at 600rpm and only attain 2300rpm. the answer is to increase the throw not cable lenth.to do it by fly by wire leaves you very vurnable to electrical mishaps and this is critical to safety.

Posted: Jan 25th, '10, 12:56

by bob lico

i should mention total throw on the fuel injection pump lever for cummins is 21/4" and you really need 21/2" to ensure dead idle with tension.

Posted: Jan 25th, '10, 15:46

by Mikey

Bob,

Keep us posted as I have a bit of the same problem. Don't worry so much as I don't run WOT very often but would like the option.

Pictures as always are appreciated.

Posted: Jan 25th, '10, 18:09

by Rawleigh

Bob: I am not real familiar with the Cummins injector pump. Does the injector pump have lever on the side that the cable attaches to or is there some other mechanism? If it is a lever type, shorten the lever on the pump. I am sure it is not that simple though or you guys would have thought of it. Do you have a picture or the throttle cable to pump linkage that you or Mikey can post?

Posted: Jan 25th, '10, 18:20

by bob lico

the cummins 330/370 hp has a vertical lever with three holes from top to bottom. i am in the bottom hole allready and can`t go down any further on the lever (shortest throw).the lever moves from 45degrees to the right to 45 degrees to the left (wot). there is a bracket about 4" away with stardard sae drilling for U bracket to hold outter cable.

Posted: Jan 26th, '10, 09:26

by Rawleigh

Sounds like you are on the right track using another lever on a bracket nearby to increase the throw. You can use spherical end bearings on an adjustable rod to link the two.

Posted: Jan 26th, '10, 10:09

by Rocky

Pictures Bob, of the linkage please!

Posted: Jan 26th, '10, 14:46

by Carl

I think I understood Bob. You want to increase the throw from 1-3/8 to 1-3/8 plus.

Here a rough sketch of what I have in mind. I'd incorporate standard cable mounting hardware to secure cables to bracket and to adjusting rod. The higher cable I'd use one of the adjustable cable clamps to give infinite adjustment ratios. Although once dialed in it could be secured permanently.

Carl

Posted: Jan 26th, '10, 15:10

by bob lico

that is exactly it carl . myself and 6 other bertram owners are desperate for this solution . one question carl ;would it be possible to use a stainless threaded rod like 10-32 thread about 8" long instead of a second cable.it would be differcult to get 33c surpreme in such a short lenth.

Posted: Jan 26th, '10, 16:28

by Carl

I guess you could, but alignment becomes more of an issue.

I think, I have seen Standard cables down around 2'. Not 33C Supremes.

The 33C's can be made to order. I usually have that done at SeaLand Power. Cost was about the same as "off the shelf".

http://www.sealandpower.com/

Posted: Jan 26th, '10, 17:28

by bob lico

ok then i will use a cable . with that in mind i could use your bellcrank under the bridge and a short cable to the helm unit .funny how they made a beautiful single lever control that works effortlessly and built with 316 stainless rack and gears , bronze bushings with a solid mounting plate but built it with 13/8" foward throw and 13/8" reverse throw . good for gears but yanmar,cummins.catapillar all have a 21/2" travel from idle to wot. like having kate hudson for the night and then she tell you she has aids!!!

Posted: Jan 26th, '10, 17:38

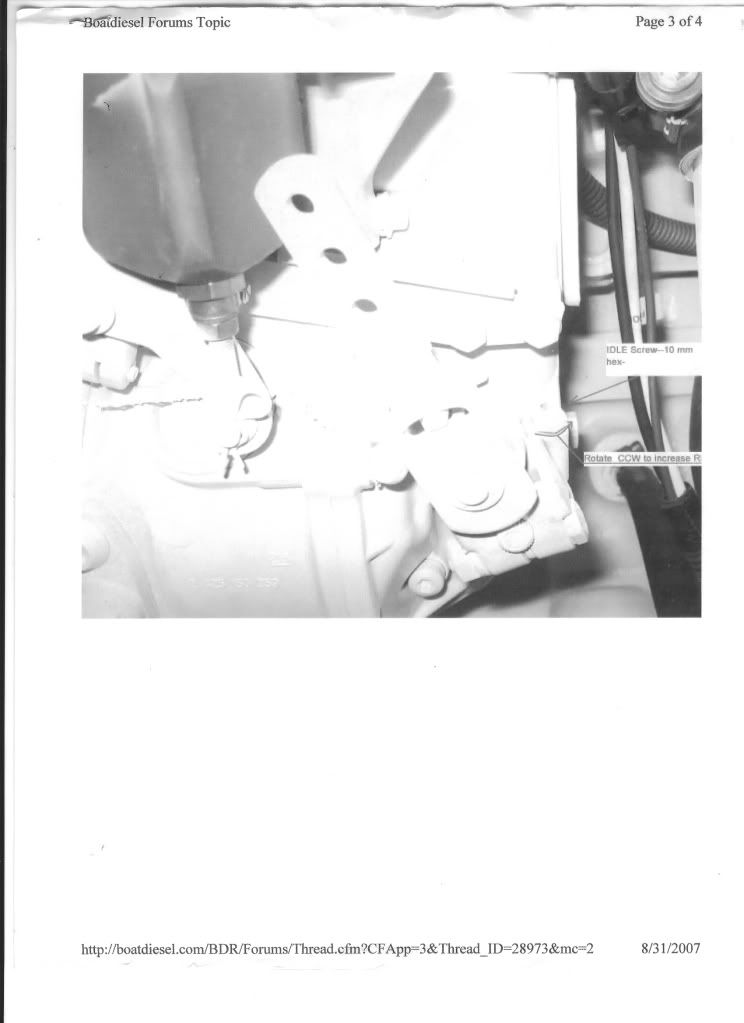

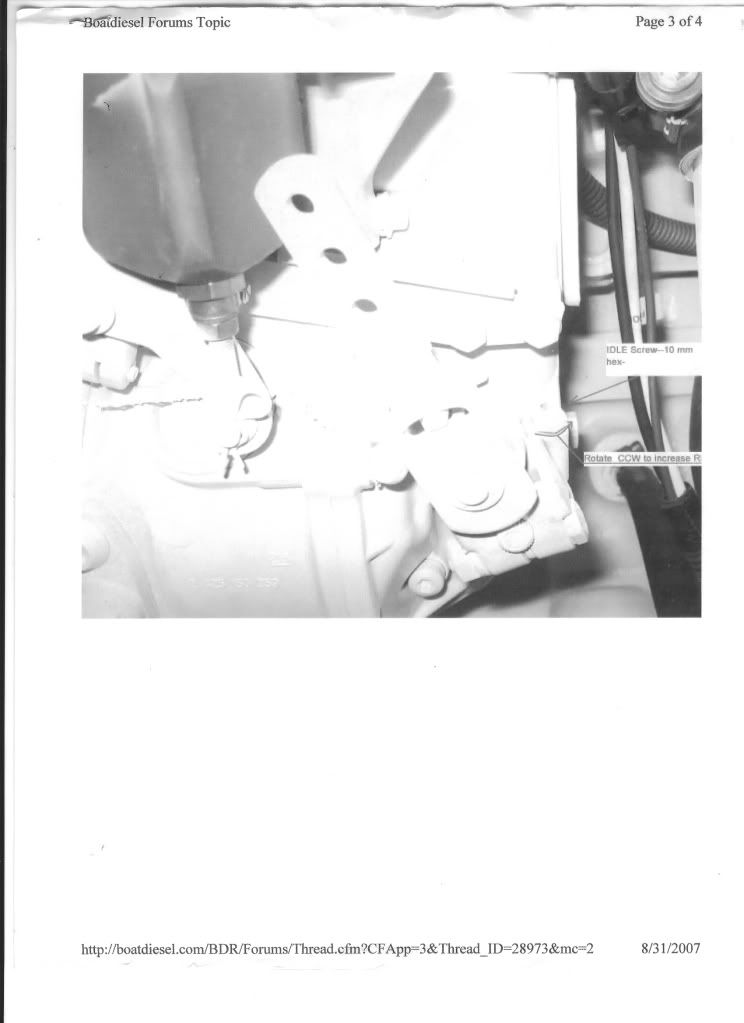

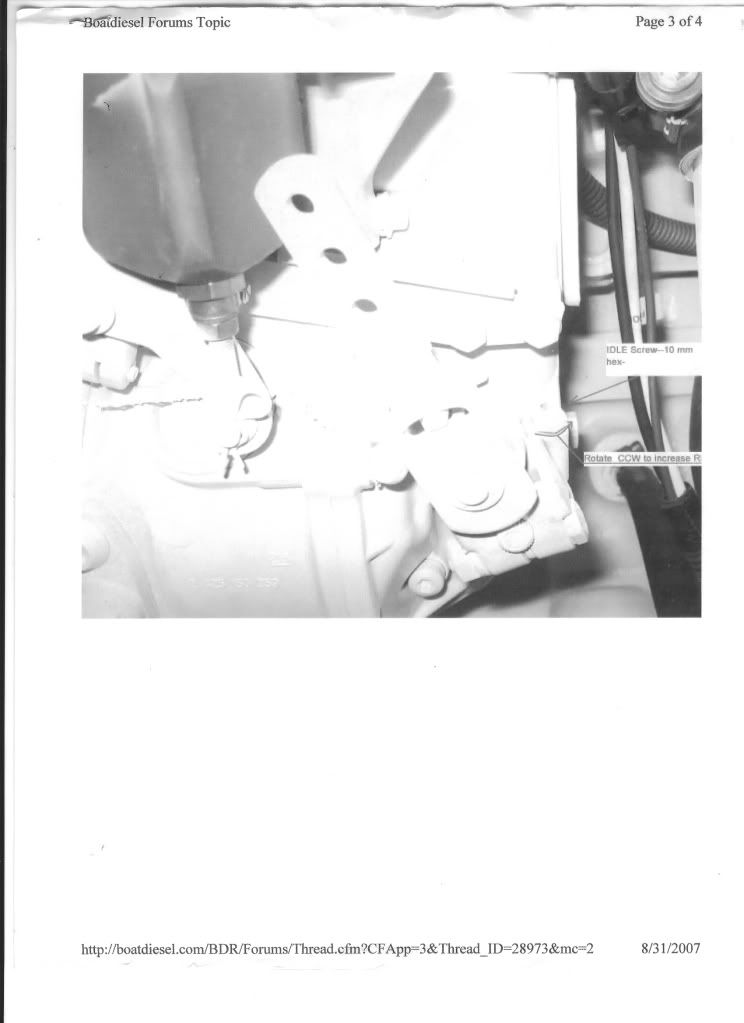

by bob lico

here is a sheet from instructions ,as you can see a rocket sciencetist could not make this work directly.

Posted: Jan 27th, '10, 00:21

by Rocky

Carl, great design. The only thing I would do maybe to add to this would be to incorporate pivot bearings to decrease resistance because you will definately have an extra EFFERT required to push and pull this "less advantage" linkage. Just a thought.

Posted: Jan 27th, '10, 08:15

by Carl

Bob, while I believe my idea would work. I would prefer to keep simpler.

My First Choice--Can you increase throw at the shift lever by extending the slot you attach the cable or by adding an extension to the lever? Moving away from the pivot will increase throw to the cable.

My Second Choice-If you cannot increase throw at the control, can you move the attachment point at the motors linkage? I am not sure what the linkage attachment looks like there, but you should be able to move the attachment point closer to the pivot point which in essence gives you more throw for your 2-3/8" cable travel. This can be done Drilling a new hole, slotting (as shown) or make a reverse extention or new Motor Throttle Bracket to accept an attachment point closer to the pivot.

My third choice would be to add the previous sketched bracket and extra cable.

Posted: Jan 27th, '10, 09:37

by bob lico

carl first of all on behalf of myself and the 6 others that have pm. me i would like to give you a sincere thank you for putting your expertise into this post ,as you understand what a inconvience this has cause.

i will photo engine linkage today. actually it is a simple lever 3/8" wide by 2" long that goes from idle position to wot by moving back and forth with about 90 degrees of travel (45 back and 45 forward). i am allready at the bottom hole in the lever.the picture i posted is only part of the thottle let me illustrate and better propective.

Posted: Jan 27th, '10, 09:53

by bob lico

the first illustration shows from the pivot point this is the actual way the lever is monted in the control head,

Posted: Jan 27th, '10, 10:01

by Rawleigh

Bob: The question is are you as far down the lever on the pump as you can go with with the cable end and not have it bind against the shaft when fully extended. You will probably have to drill a new hole.

Posted: Jan 27th, '10, 10:07

by bob lico

you really can not drill a hole further down.

Posted: Jan 27th, '10, 10:13

by bob lico

rawleigh there is a wound (circular) spring in back of lever not seen in photo at pivot point. also in foward position (wot) a lower hole would bind with spring mechanism.

Posted: Jan 27th, '10, 10:17

by Rocky

Judging by linkage picture, looks like third option of carls, but use this bracket AT the linkage with a ball and socket on each end of a solid rod instead of 2nd cable.(if you have the room there?) Just throwin ideas.

Posted: Jan 27th, '10, 11:21

by Carl

Your right, it doesn't appear to be much room at the control head to move linkage without obstructing cover.

On the other hand, at the motor I think you have options, although very hard to see everything in the picture. Cannot make out Spring Mechanism

It appears to be a simple lever. If you cannot just go a bit lower without obstructing something...

-Can we cut and weld the lever a bit further from the obstruction.

-If material is soft, tweak with a little bend for clearance

-Piggy back an extension, as drawn.

I like to keep things real simple and straight forward. It just make any issue easier to diagnose and fix quickly.

If your not in a rush, I'd be glad to take a ride out one weekend for a firsthand peek.

Posted: Jan 27th, '10, 12:05

by Mikey

Guys,

This is a problem with Kobelt, as I understand, and is plaguing several of us. They sell their shift units with the proviso that it works on our equipment. Why don't we submit this to them? My Cummins(300) have NipponDensa pumps. Different than what it appears you are showing. However they all have (as I understand) 1 3/8 throw. Kobelt says their units work with this. Why not get them involved?

Posted: Jan 27th, '10, 16:49

by bob lico

carl i took a photo of linkage .the top hole is a 3" travel the second hole is a 21/2" travel and the third hole is a 21/4" travel.needless to say on the third hole the boat is like holding back a team of horses from o to 683 lbs of torque in such a short throw; not cool for the ladies.